The FIFI4MARINE M-SKID is a standalone, PLC-controlled 24/7 detection and activation CAFS fire suppression system that can be used where a fire load or exposure to high temperatures needs to be controlled, originating from inside the battery system or from outside the battery system as an external fire load.

In case of an event, the foam injection system is automatically activated by remote signals coming from gas and fire detection sensors or from the battery management system.

Using compressed air, the Bio4C premix is transformed into a unique Hybrid and Durable firefighting foam.

The produced foam is applied through pipes and channels into selected battery systems, creating an immediate cooling effect. Greatly reduces temperatures to safety levels and prevents spread to surrounding modules.

To prevent fifi foam injection in all battery arrays, a unique automated zone selection electrical valve manifold is used to select and inject only the battery arrays in which gas or excessive temperature is detected. All other battery arrays in the battery room that are in a safe situation are not injected and remain fully operational for 100% manoeuvrability and ship safety.

The system can be configured to inject foam into individual modules, complete racks or complete strings. The most cost-effective system architecture is to design the system to electrically disconnect each string and fill that particular string with foam, leaving all unaffected strings in operation.

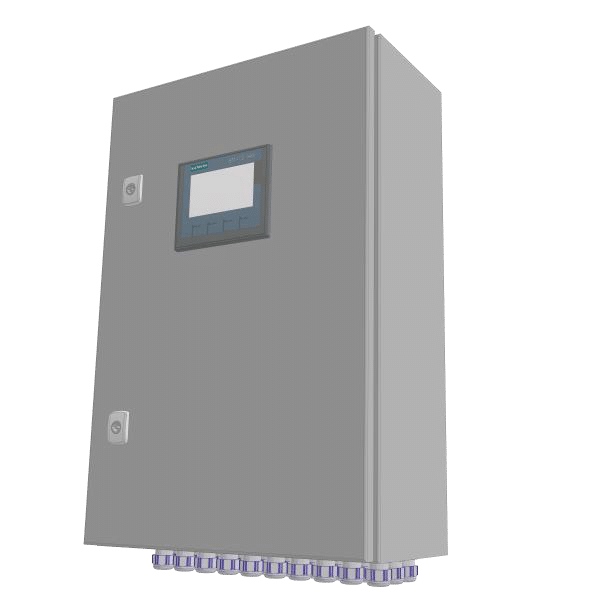

The FIFI4MARINE M-SKID is fully stand-alone controlled by the FAM DAP Switch Cabinet. This WAGO PLC-based controller provides limited wired signalling to an alarm and monitoring system in addition to functional control. For more detailed information, a Modbus TCP connection is available as standard. The HMI in the front door provides local status display and alarm confirmation. Finally, all events and activations are logged internally, log file can be made available on request.

- Non-chemical biological foams are sensitive to sub-zero freezing

- System weight may vary due to custom system requirements

M-SKID technical specifications

Operating voltage | 5.5 Bar |

Extinguishing agent | F4M-BIO4C Eco foam |

Temperature range* | >5°C <60°Celsius |

M-SKID Series | M-SKID-300 | M-SKID-450 | M-SKID-600 | M-SKID-900 |

Pre-mix capacity | 300 L | 450 L | 600 L | 900 L |

Dimensions (H x W x D) | 2000 x 675 x 1100 mm | 2000 x 675 x 1100 mm | 2000 x 675 x 1865 mm | 2000 x 675 x 1865 mm |

M-skid Weight dry * | 95 kg | 150 kg | 195 kg | 230 kg |

HP Air bottles weight | 55 kg | 75 kg | 110 kg | 150 kg |

Premix filling | 300 kg | 450 kg | 600 kg | 900 kg |

M-skid Total operating weight | 450 kg | 675 kg | 905 kg | 1280 kg |

* Dry weight of the C-SKID excluding premix, air cylinder, cabinet, manifold and pipework

DAP electric cabinet

Detection and activation box

Item number | 4.A.0000 |

Height | 600 mm |

Width | 400 mm |

Depth | 210 mm |

Weight | 28 kg |

Colour | 400 pre-polished stainless steel |

Material | AISI 316 pre-polished stainless steel |

IP value | IP 65 |

Current | 230VAC-2A / 24VAC-10A |

UPS battery capacity | 7Ah 24VDC |

UPS Max. power | 24V/10A |

PLC control system | WAGO 750-8100 |

HMI | WAGO TP600 |

Monitoring and control capacity | 1 M-SKID and 1 - 12 valves with 2 - 24 sensors (gas and temperature) |